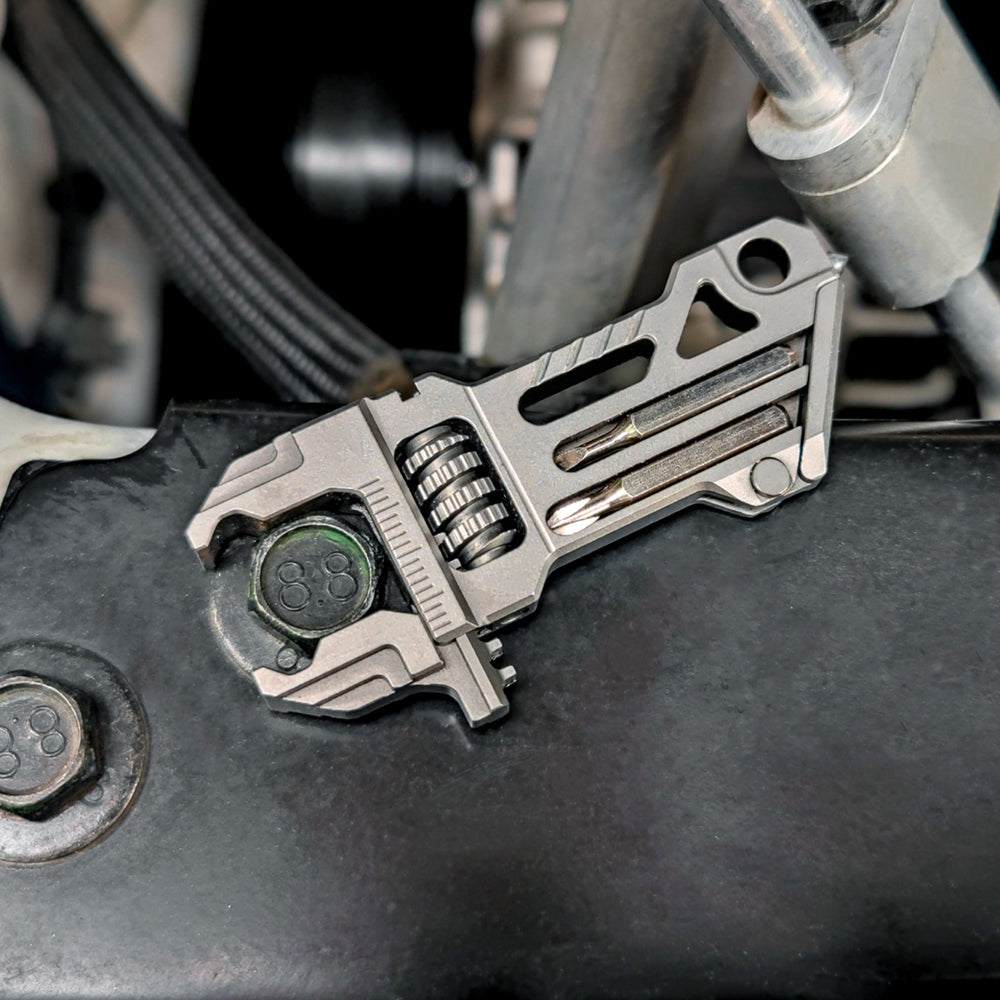

What is CNC Machining?

CNC machining is a technology widely used in precision machining, covering aerospace, automotive manufacturing, medical equipment, mold manufacturing and many other industries. In these industries, CNC machining not only improves production efficiency, but also improves product accuracy and consistency.